Engine cooling for passenger cars

To keep pace with ever rising demands to improve fuel consumption, emissions, and passenger comfort, engine cooling is increasingly morphing into the complex task of thermal management. MAHLE has the knowledge and expertise to develop and implement holistic cooling circuit solutions for the engine, charge air, interior air conditioning, and hybrid components such as the electric motor, battery, and power electronics.

Engine cooling components, modules, and systems

Battery cooling

The increasing electrification of the powertrain is one of the biggest technological trends in the automotive industry. In order to cool the lithium-ion battery and the power electronics of hybrid and electric vehicles, temperatures of below 40°C have to be reached, which is accomplished by interlinking the low-temperature and refrigerant circuits. This results in new, complex circuits that place significantly higher demands on the individual components and the control system.

Charge air cooling

One of the chief measures used to reduce fuel consumption and thus CO2 emissions is to reduce the swept volume, typically in combination with turbocharging, in order to maintain or improve power output and torque. As the degree of turbocharging increases, the necessity of cooling the compressed air grows simultaneously. Charge air cooling therefore takes on an ever more critical role. The latest stage of development at MAHLE includes indirect cascaded charge air cooling, integrated in the intake pipe, which provides minimal pressure loss and significant packaging advantages. It produces charge air temperatures close to that of the coolant by using a two-stage cooling process.

Coolant pump

Reaching the optimal operating temperature of a combustion engine more quickly is one of the remaining levers for further reducing CO2 emissions in vehicles. Keeping the coolant flow at a standstill after cold-starting the engine supports an effective warm-up phase, as the coolant in the engine will not immediately dissipate any heat generated by the engine.

MAHLE has developed a hydraulically controlled coolant pump, a system that due to its simple and robust design has a low system weight and can be adapted to existing engine cooling circuits.

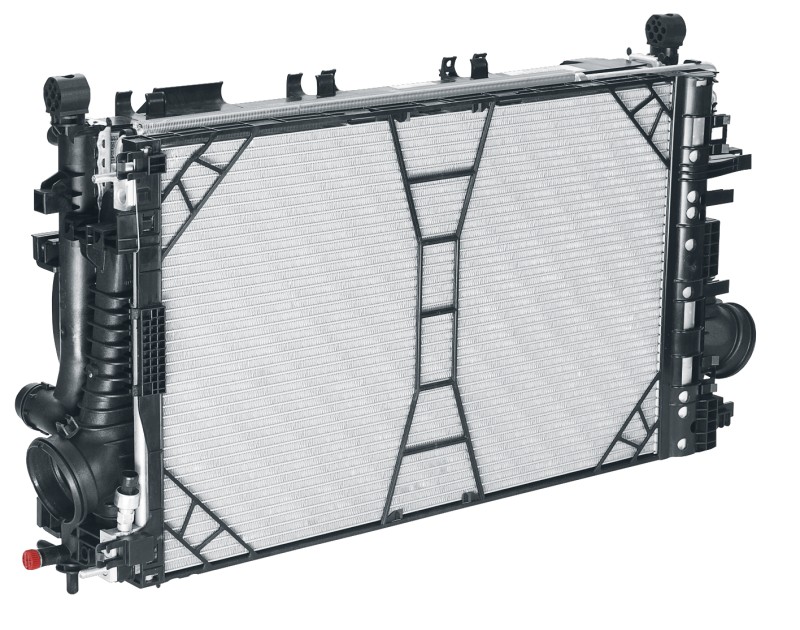

Cooling modules

Cooling modules comprise multiple engine cooling components as well as the condenser, which forms part of the air conditioning circuit. For maximum efficiency, all components are optimally matched. The modules are assembled according to the vehicle design concept, thus reducing development, production, and logistics costs.

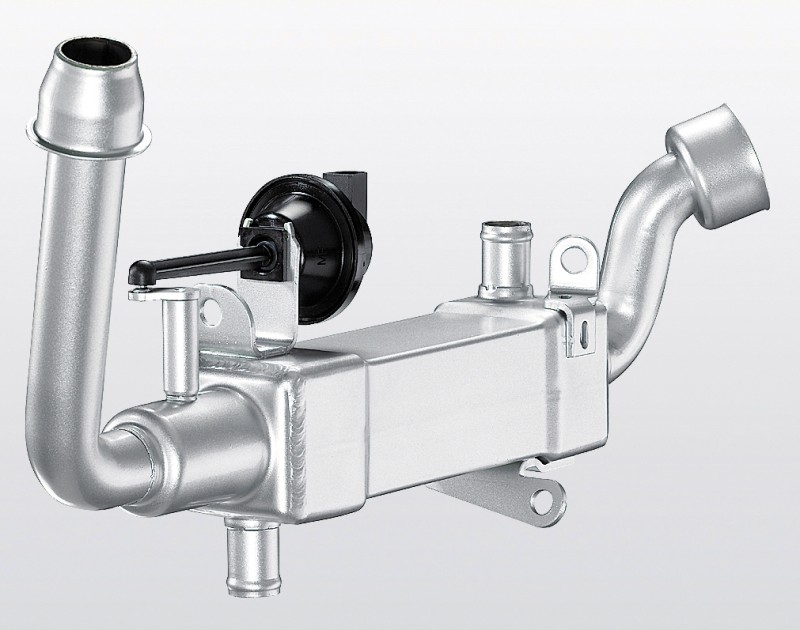

EGR coolers

The new emissions standards for diesel passenger cars and commercial vehicles can no longer be met with adjustments to the engine alone. One approach to complying with the new emissions limits is to incorporate cooled exhaust gas recirculation (EGR). This involves extracting a portion of the main exhaust flow between the engine outlet and the turbine, cooling it in a special heat exchanger, and feeding it back to the intake air downstream of the charge air cooler. The combustion temperature in the engine is thereby lowered, thus reducing the formation of nitrogen oxides (NOx). The cooled EGR technology has been available in series production passenger cars since1999. In gasoline engines, cooled EGR will be implemented in the coming years to reduce fuel consumption. One outstanding feature of MAHLE’s laser-welded exhaust gas heat exchangers is their excellent corrosion resistance.

We also offer switchable exhaust gas heat exchangers featuring a bypass section integrated into the cooler housing. To keep pollutant emissions at a constantly low level, the bypass disables the recirculated exhaust gas cooling function in certain driving situations, e.g., during the cold start phase.

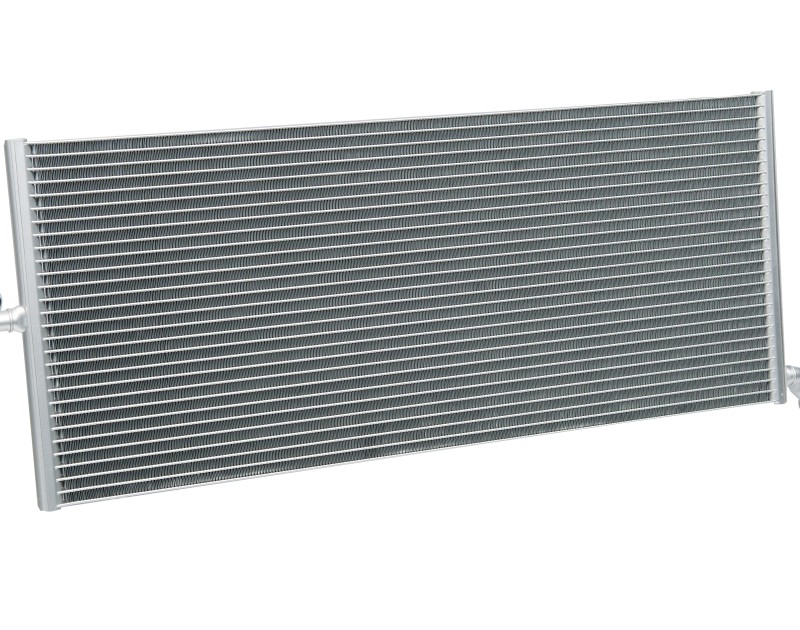

Low temperature radiators

In an indirect charge air cooling system, rather than being released directly to the ambient air, the heat from the charge air cooler first passes through a separate, low-temperature coolant circuit (LT cooling circuit) before being discharged to the ambient air by a downstream, low-temperature radiator (LT radiator).The LT radiator of the indirect charge air cooling system is mounted onto the engine cooling module and can be designed more compactly than the direct charge air cooler, without sacrificing performance. This is because heat is transferred from the air to the coolant. The LT radiator can also be optionally used to ensure optimum thermal management of a temperature-sensitive lithium-ion battery, its power electronics, and soon also the condenser of the refrigerant circuit.

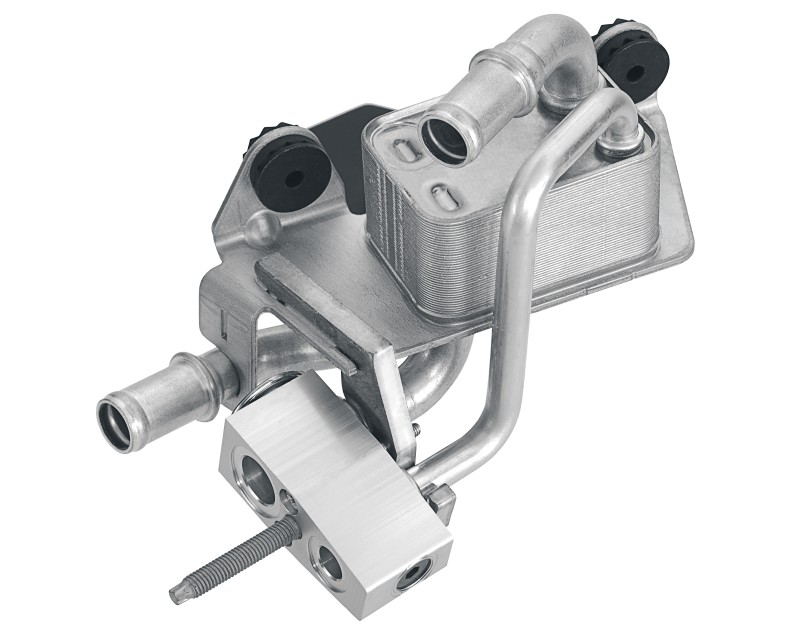

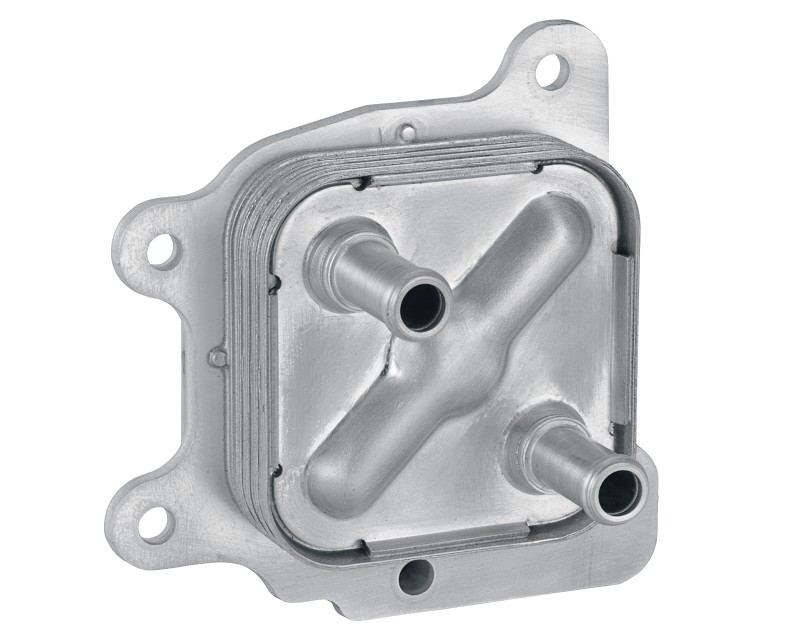

Oil heating and cooling systems

Heat exchangers for heating and cooling modules typically have a lamellar design and ensure an as balanced as possible thermal cycle for lubricating oils in the engine and transmission. This allows the lubricant to heat up quickly, which significantly reduces fuel consumption at cold start. At high oil temperatures, heat exchangers prevent overheating and premature aging of the oil, allowing oil change intervals to be extended.

Current MAHLE heating and cooling modules are also able to handle channel guidance, temperature regulation, and filtering of the coolant flow. An optimized channel guidance and distribution of the coolant flow provides coolant to the heat exchangers of the engine and transmission as well as for fuel as needed.

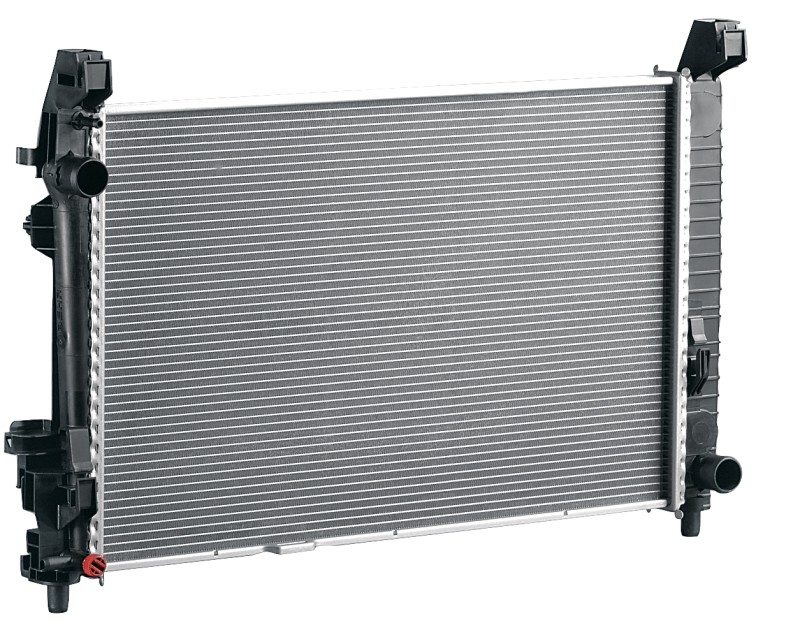

Radiators

The most important component of the cooling module is the radiator, which consists of the radiator core and plastic tanks with all requisite connections and fastening elements. The radiator core is usually made of aluminum, while the coolant tanks are made either of aluminum—just like the core—or fiber glass-reinforced polyamide.

Thermostats and control valves

The wide variety of engine cooling tasks can be achieved only by intelligently controlling the energy flows that arise. Various systems and engine components must be supplied with coolant as required. In modern systems, this takes place with different temperature levels and separate cooling circuits. Intelligent control systems from MAHLE, such as engine operating map thermostats, ensure demand-actuated and precise temperature regulation and thus promote more efficient operation, reduced consumption, less wear, and lower emissions.

Electric coolant pumps

Based on a modular design, MAHLE offers a 12V pump with up to 800 watts electrical power consumption and a 24V pump with up to 1kW.

Due to the individually controllable coolant flow with low mechanical losses, our customers achieve significant reductions in fuel consumption and up to 5% lower carbon dioxide emissions (CO2).

The brushless electric motor as well as the bearing concept ensure maintenance-free operation with high reliability. Besides that, the directly cooled electronics allow a maximum power utilization.