Air management for commercial vehicles

Air management in vehicles starts with the air section, from the unfiltered air intake through filtration to induction by the intake module to the combustion chambers. It continues with the turbocharging system, with an exhaust gas turbocharger and charge air cooling, as well as controls and temperature management for exhaust gas recirculation.

Systems for air management

Oil mist separator

Crankcase ventilation systems reliably remove the gases from the crankcase that are contaminated with oil mist. The oil mist separator integrated into the ventilation separates gaseous and liquid components. The separated oil is recirculated into the oil circuit and the residual air is recirculated into the intake system. The oil mist separator must ensure a high level of oil separation for all engine-specific requirements that lead to varying volume flow rates and fluctuating amounts of oil. Active oil mist separation achieves this at a consistently high level, regardless of the engine operating conditions. This solution also enables active management of gases and testing of the ventilation system to ensure its integrity and proper operation.

Air intake systems

MAHLE air intake systems include the entire scope of the system, from raw air intake with preliminary removal of dust and water to the air filter module with the main filter element and safety insert to the turbocharger inlet interface. As a result, MAHLE is able to fully respond to system inquiries and to develop and produce modules completely in house.

Air filter modules

Critical package constraint situations present a formidable challenge to the development of air filters for commercial vehicles. MAHLE air filter modules are individually customized according to customer requests with regard to package constraint, weight, and interfaces to other systems. Another development focus of MAHLE is on achieving long maintenance intervals. Mechanical and electrical sensors reliably display the maintenance status of the filter system. In addition to customer-specific solutions, MAHLE also offers Modular Concepts, a modular system that can be configured to meet customer requirements.

MAHLE is also a leader in environmental protection. Metal components are therefore eliminated as early as in the design phase of the air filter modules, in order to simplify the disposal of used filter materials.

Electrical heaters for blow-by systems

Electric blow-by heaters are used between the air intake module and the cylinder head cover to prevent icing. They work with PTC technology and are available in modular versions within a power range of 200 to 600 watts. The optimized heating function and the possible high level of integration into the motor periphery are advantages of the MAHLE heaters.

Cylinder head covers

Thermoplastic cylinder head covers meet the highest requirements for function, functional integration, and design. These products provide maximum stability at low weights. They meet high requirements with respect to engine acoustics and leak tightness, as well as the increased design demands by vehicle and engine manufacturers. The latest generation of MAHLE cylinder head covers for commercial vehicle has even more to offer: it allows functional integration, such as an integrated oil mist separator, and is modular in design so that it can be used cost-effectively in engines with different numbers of cylinders.

Oil pans made of plastic

The plastic oil pan enables relevant weight savings, while integrating a broad range of functions. The material’s insulation properties make it possible to store heat, thereby reducing frictional losses during engine restarts. Realization time and economic efficiency are improved thanks to the newly developed tool and production concept.

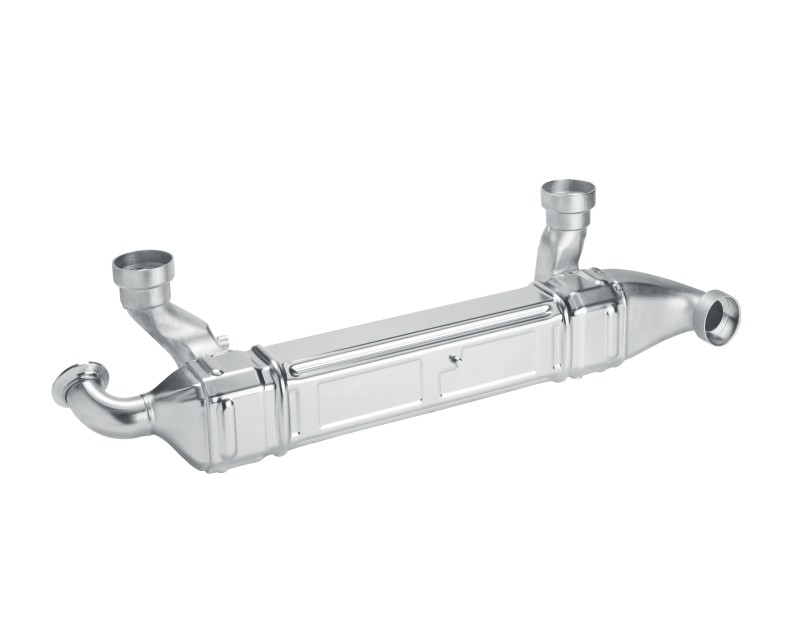

Exhaust gas recirculation (EGR)

One approach to meeting the NOx (nitrogen oxide) emissions limits is to incorporate cooled exhaust gas recirculation (EGR). This involves extracting a portion of the main exhaust flow between the engine outlet and the turbine, cooling it in a special heat exchanger, and feeding it back to the intake air downstream of the charge air cooler. The combustion temperature in the engine is thereby lowered, thus reducing the formation of NOx. Our EGR coolers offer exceptional thermomechanical strength, reduced tendency to sooting, and outstanding specific performance. Thanks to the use of high-performance winglet tubes, extremely stable EGR temperatures—and thus improved EGR control—can be achieved.