Fuel management for commercial vehicles

Fuel management in commercial vehicles mainly refers to filtration and water disposal. The trend toward a so-called world engine—an engine platform for use in every region on earth—gives rise to considerable technical challenges. Depending on the region, this concept is confronted with different biofuel content and fuel quality levels. It is therefore necessary to facilitate optimal fuel treatment in all conditions.

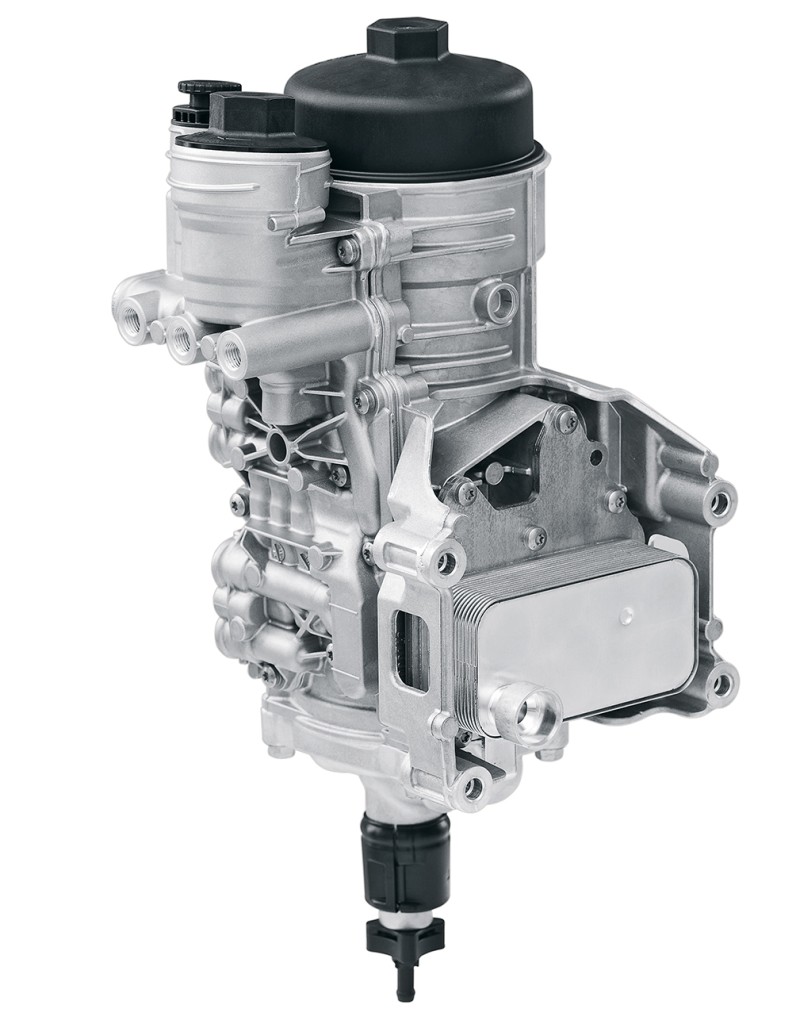

Systems for fuel management

Fuel filters

Fuel filter modules for commercial vehicles efficiently prepare diesel fuels for the combustion process. For this purpose, they use high-separation filter media and feature an advanced functionality scope. For diesel engines, the functional range of the MAHLE fuel filter modules can be rather complex. The fuel can be cooled or heated, for example, or the water content of the fuel can be separated.

Water separation systems

In order to comply with demanding emissions limits, modern diesel engines typically employ common rail injection systems. These are extremely sensitive to solid particles and diesel fuel containing unsolved water. Since world engines are also used in countries with poor fuel quality and varying shares of biofuel, it is necessary to enable optimal separation of contaminants and water even under these conditions.

Once it has achieved a certain level, the separated water in the fuel filter must be drained. This can be done automatically or manually using a drain plug. Automatic water disposal takes place either semi-automatically in the prefilter on the suction side or fully automatically in the main filter on the pressure side by means of a solenoid valve.

Electrical heaters for fuel systems

These individually adapted heaters are used for cold starts and operation at low ambient temperatures. They are characterized by a low pressure loss during high heat transfer into the medium, a robust design, low energy consumption and high performance up to 600 watts, controllable via integrated electronics or engine management. The PTC heating element with integrated overheating protection offers maximum safety.

Water level sensors

Water level sensors for fuel filter modules determine whether too much liquid are collected in the assembly during operation. With our new technology, the sensor elements are no longer made of metal but of conductive plastic, thereby preventing electrolysis problems. With operating voltages from 9 to 36 volts, the sensors are suitable for a broad range of applications.

CleanLine family of commercial vehicle prefilters

The new CleanLine prefilter family is a modular building block system developed specifically for countries with low fuel quality. The prefilters are available in various sizes, with a choice of single- or multistage water separation. Additional optional functions include a hand pump, temperature or pressure sensors, water level sensors, and manual or automatic water disposal.

Ion exchanger for fuel cells

MAHLE already supplies second-generation ion exchangers for fuel cell vehicles. Ion exchangers are used to lower the conductivity of the coolant in the fuel cell to the very low levels required. This is necessary to prevent damage to the fuel cell stack’s sensitive membrane due to minor short circuits caused by the conductive coolant.